How to Rate the Criticality of Your Equipment

Key Takeaways

Rating equipment criticality ensures maintenance efforts are focused on the most crucial areas to maximize plant uptime and reliability.

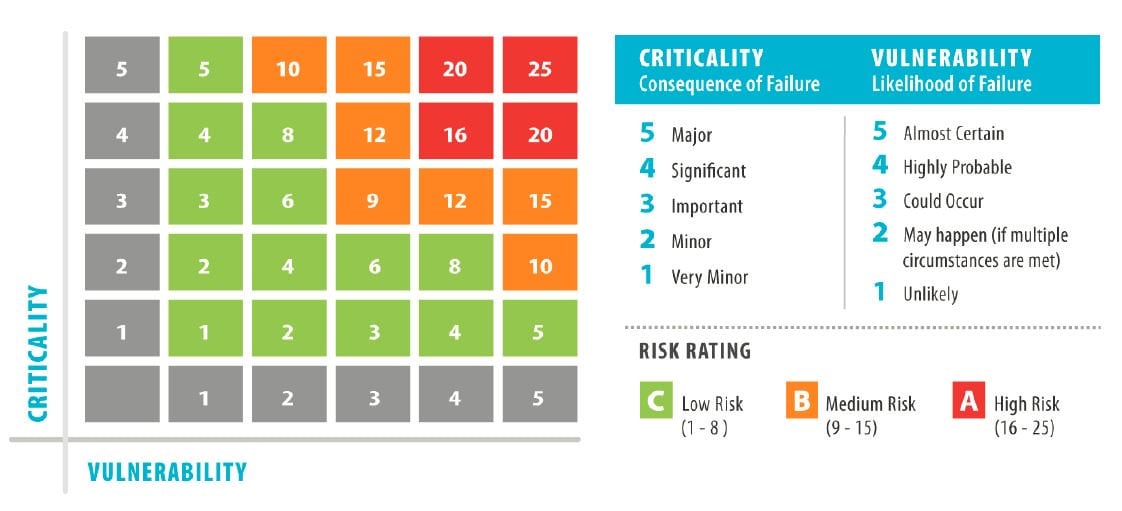

A structured approach to assessing equipment criticality involves evaluating vulnerability and criticality, forming an assessment team, and using a risk matrix.

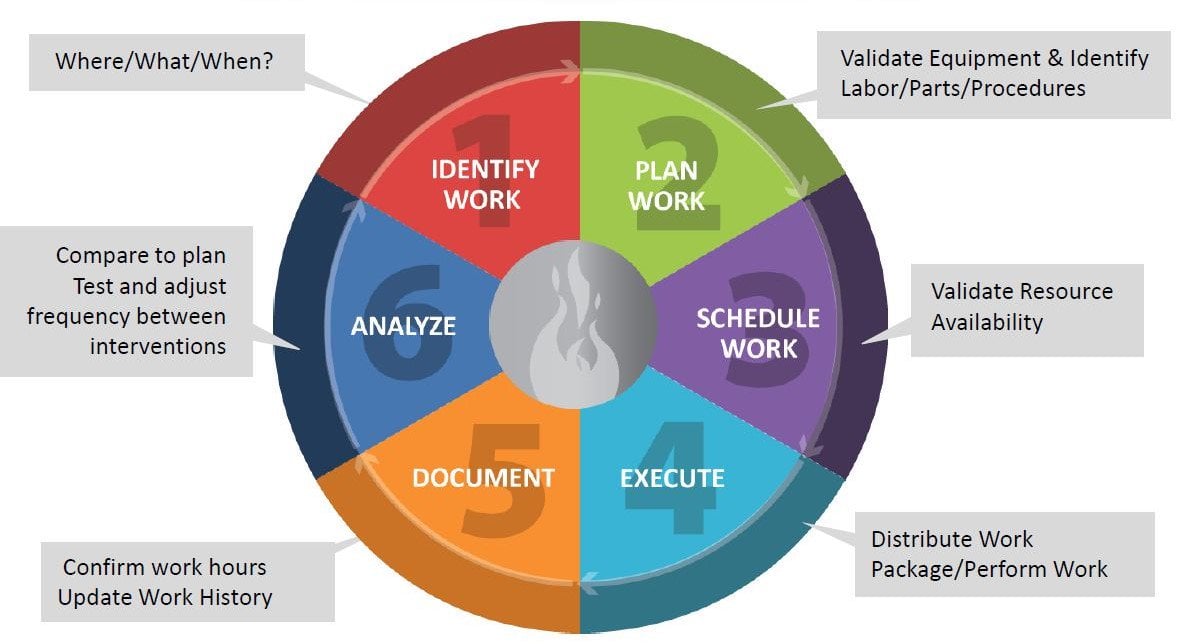

Implementing criticality-based prioritization and reporting optimizes maintenance scheduling and resource allocation, reducing plant interruptions.

Rating equipment criticality is an important part of a strong preventive maintenance plan. By giving your equipment a rating and setting up guidance rules, you can ensure that your maintenance and engineering efforts are focused in the correct areas.